It is widely acknowledged that most professionals in the Injection Molding and related industries have heard of Plastic OverMolding. Furthermore, the likelihood of encountering products manufactured using this technology in daily life is quite high. However, the specific process details may remain unclear even to those working within the injection molding field. Indeed, Overmolding represents a relatively broad concept. This article provides a comprehensive overview of the relevant Overmolding technology.

Industry Definition: Plastic Overmolding refers to an injection molding process where multiple materials with different properties are processed through secondary or multiple molding cycles, enabling them to overlap and securely interlock or bond tightly together.

Classification: Overmolding is generally categorized into two types: Insert Molding and Two-Shot Molding.

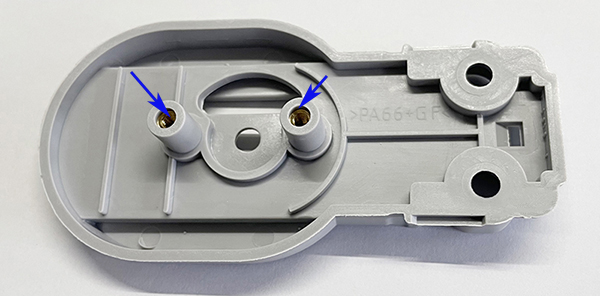

Insert Molding is a process where pre-prepared dissimilar material inserts (primarily metal) are placed into a mold, followed by resin injection. The molten material combines and solidifies with the resin to form an integrated product. It is currently the most commonly used secondary molding method for overmolding soft elastomers onto rigid engineering plastics.

Characteristics: This method requires minimal hardware configuration and investment. During the insert design phase, the rigid segments are pre-positioned within the mold, followed by elastomer injection.

Bonding Mechanism: The elastomer acts as the bonding agent, achieving adhesion through mechanical locking, physical melting, or chemical bonding. For chemical bonding to occur, the elastomer must be sufficiently hot to melt the surface layer of the rigid substrate.

Process Enhancement: Improved bonding can be achieved by preheating the insert segment prior to overmolding. Compared to Two-Shot Molding, Insert Molding is more widely applied in practice.

Ubetter Plastic's Expertise in Insert Molding: Based on years of successful development experience in Insert Molding, the following characteristics have been summarized:

1. Synergistic Material Properties: Combining the easy moldability and flexibility of resin with the rigidity, strength, and heat resistance of metal enables the robust production of complex and intricate metal-plastic integrated products.

2. Electrical Functionality: Particularly, utilizing the combination of resin's electrical insulation and metal's conductivity allows the produced components to fulfill the fundamental functions required for electrical products.

3.Streamlined Assembly: The prior forming and assembly of multiple inserts result in more rationalized post-processing for product unit integration.

4.Diverse Insert Materials: Insert components are not limited to metal; they also encompass a wide range of materials such as fabric, paper, wire, plastic, glass, wood, coil components, and electrical parts.

5.Enhanced Reliability: Since molten material bonds directly with the metal insert, the gap design around metal inserts can be narrower compared to press-fit methods, leading to higher reliability in composite product molding.

6.Protection of Delicate Parts: By selecting appropriate resins and molding conditions, even easily deformable or fragile components (e.g., glass, coils, electrical parts) can be securely sealed and fixed within the resin.

7.Complete Encapsulation: With suitable mold design, inserted parts can be fully encapsulated within the resin.

8.Complex Geometry: Following insert molding, products with hollow cavities or grooves can be created through core removal processes.

9.Automation Potential: Combining vertical injection molding machines with robotics and insert alignment systems enables highly automated insert molding production.

Two-Shot Molding refers to a manufacturing process or production unit where multiple plastic materials are combined into a single multifunctional component. This technology utilizes multiple materials in injection molding production, integrating the properties of different materials during the molding process through assembly or suitable bonding methods to enhance product functionality and aesthetics.

Industry Significance: As one of the increasingly popular advanced injection molding methods, Two-Shot Molding offers significant cost-saving potential and novel design possibilities for product manufacturing. The following section examines the current development status and trends of Two-Shot Molding, with particular emphasis on its applications in automotive, medical, and data center industries.

Ubetter Plastic's Technical Solutions: Based on client cost requirements and equipment availability, Ubetter Plastic's Two-Shot Molding implementation can be categorized into two approaches:

a) Secondary Injection Molding Technology:

Produces two-color products using two separate molds on different machines. This method offers relatively low costs and has no machine restrictions (no specialized two-shot machine required), resulting in lower investment pressure for both clients and the company. However, production efficiency is relatively low. Exemplary products manufactured using this technology based on client specifications are illustrated below:

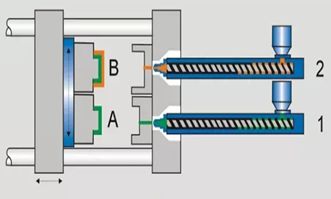

b) Dedicated Two-Shot Molding Technology:

Injects two plastic materials using the same injection molding machine, involving two molding cycles while requiring only one demolding operation. Commonly termed bi-material injection, this process typically utilizes a specialized mold set and requires dedicated two-shot injection machinery. Two-shot molds are gaining prominence in the market due to their ability to enhance product appearance, facilitate color changes, and eliminate the need for painting. However, this technology entails higher costs, demands advanced technical expertise, and delivers higher production efficiency.

Ubetter Plastic's Technical Expertise: Based on years of successful development and molding experience with both technologies, the following characteristics have been summarized:

1. Mold Cavity Design: The two cavity shapes differ, each forming one product component, while both core shapes remain identical.

2. Mold Rotation Precision: After 180-degree rotation around the center, the front and rear molds must align perfectly. This necessitates rigorous checks during design, imposing higher accuracy requirements for mold base positioning and machining.

3. Runner Ejection: For three-plate molds, the runner system should ideally be designed for automatic ejection. Particular attention must be paid to the feasibility of ejecting soft material runners.

4. Secondary Cavity Clearance: To prevent the secondary cavity from scratching the first molded plastic part, clearance spaces can be designed. However, the strength of every sealing area must be carefully evaluated to avoid plastic deformation under high injection pressure, which could potentially cause weld lines during the second shot.

5. First Shot Dimensions: During injection, the first molded part can be slightly oversized. This allows tighter compression against the core during the second molding cycle, enhancing the sealing effect.

6. Melt Flow Impact: Potential flow-induced deformation of the first molded part during the second injection must be assessed. If identified, corrective measures are essential.

7. Core Component Sequencing: Before mold closing, verification is required to ensure core-side sliders or lifters do not reset prematurely and damage the product. Mechanisms must ensure core/cavity closure occurs before core-side component resetting.

8. Cooling System Uniformity: Cooling channel layouts for both cavities and cores should be maximized, balanced, and consistent.

9. Material Sequence Priority: In most cases, the hard plastic component is molded first, followed by the soft elastomer, due to the latter's higher susceptibility to deformation.

Ubetter Plastic possesses extensive years of successful development and mass production experience in the fields of Insert Molding and Two-Shot Molding within Overmolding technology, having generated significant value for its clients.

As a specialized provider of injection molding solutions for Overmolding, Ubetter Plastic actively responds to the challenges posed by high technology to traditional industries through dedicated exploration and research. The company has identified new strategic balance points between conventional techniques and advanced technologies. This approach enables both Ubetter Plastic and its clients to establish their industry position and brand value during the ongoing industrial revolution.

Contact: Roy Hwang

Phone: +86-15869559228

E-mail: info@ubetterplastic.com

Whatsapp:0086-15869559228

Add: No.78, Shipoqiao Middle Road, Yuyao City, Zhejiang Provice, China

We chat