3D Printing Services for Rapid Prototyping and Low-Volume Production

Accelerate Your Product Development with Industrial-Grade Additive Manufacturing

In today's competitive market, speed is everything. Traditional prototyping methods can be slow and costly, delaying your product development cycle and time-to-market. As an established Injection Molding manufacturer, we understand the critical importance of every step from concept to mass production. That's why we offer professional 3D printing services, designed to help innovators like you rapidly validate designs, perform functional testing, and seamlessly transition to large-scale injection molding production. Leverage our expertise in both additive manufacturing and traditional manufacturing to de-risk your projects and innovate with confidence.

Our 3D Printing Capabilities and Materials

We leverage a suite of industrial 3D printing technologies to meet the diverse needs of product development, from initial concept models to functional prototypes and custom parts.

SLA (Stereolithography) for High-Detail Prototypes

Our SLA (Stereolithography) technology produces parts with exceptionally smooth surface finishes and high dimensional accuracy. It is the ideal solution for creating visually stunning prototypes for appearance validation, fit and assembly testing, and producing precise master patterns for rapid tooling applications like silicone molding. If your project demands flawless detail and a near-production-quality look, SLA is the perfect choice.

● Common Applications: Visual prototypes, master patterns, dental and medical models, intricate art and design pieces.

● Key Materials: Photosensitive Resin, Transparent Resin.

SLS (Selective Laser Sintering) for Durable, Functional Parts

When you need strength and complexity without the constraints of support structures, turn to our SLS (Selective Laser Sintering) service. This technology uses a powerful laser to fuse durable nylon powder layer by layer, creating robust, functional components. The parts are ideal for demanding applications such as functional prototypes, complex assemblies, and low-volume end-use parts. With SLS, you can design complex geometries that are often impossible with traditional methods.

● Common Applications: Functional prototypes, ducting, hinges, housings, and low-volume production parts.

● Key Materials: Nylon.

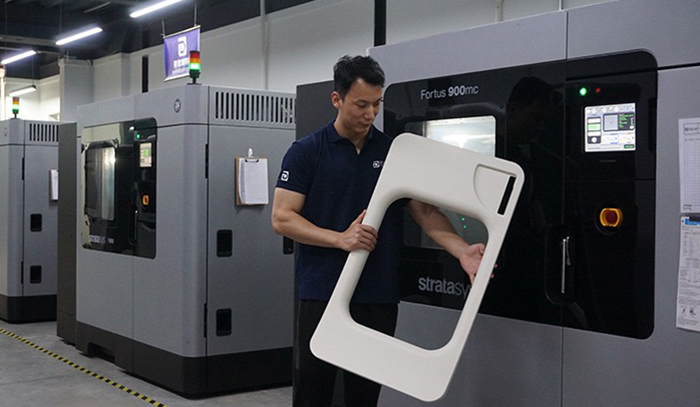

FDM (Fused Deposition Modeling) for Cost-Effective Concept Models

For rapid concept validation and large, sturdy models, our FDM (Fused Deposition Modeling) technology offers a cost-effective and reliable solution. We use a range of engineering-grade thermoplastics to build parts that are not just models but functional tools. This makes FDM excellent for creating jigs, fixtures, and large-scale conceptual models that can withstand real-world testing environments.

● Common Applications: Concept models, jigs and fixtures, large-sized parts, functional testing with specific material requirements.

● Key Materials: ABS, PLA, PETG.

More Than Just 3D Printing: Your Bridge to Mass Production

Our value goes beyond simply printing a 3D model. We provide manufacturing insights that only an experienced injection molding manufacturer can offer.

Design for Manufacturability (DFM) Analysis

Before we even start printing, our engineering team provides a comprehensive Design for Manufacturability (DFM) analysis. We meticulously review your CAD file and 3D model, providing expert recommendations to optimize your part for both 3D printing and the eventual transition to injection molding. We identify potential issues like wall thickness, draft angles, and undercuts, saving you time and cost in the long run.

Rapid Prototyping & Rapid Tooling

Speed is the essence of rapid prototyping. We can turn your CAD file into a tangible part within days, drastically accelerating your design iteration process. Furthermore, we bridge the gap between prototype and production through rapid tooling solutions. Using our high-resolution SLA parts as master patterns, we can create silicone molds for urethane casting, allowing for the production of small batches of high-quality, polyurethane parts that closely mimic the final injection-molded product.

On-Demand Manufacturing for Custom Parts

In the era of customization and agility, our on-demand manufacturing services are your strategic advantage. Whether you need a single custom part for a specialized machine, a small batch of bespoke components, or a bridge run before your injection molds are ready, we offer the flexibility and speed of additive manufacturing to meet your needs without the need for expensive tooling.

Ready to Bring Your Design to Life?

Stop letting slow prototyping delay your innovation. Partner with a manufacturer that understands your entire journey from a 3D model to a market-ready product.

Upload your CAD file today and receive an instant, interactive quote. Our additive manufacturing experts are also on standby to help you select the perfect 3D printing technology and material for your project's success.

Upload Your CAD File for Instant Quote

Why Choose Us for Custom 3D Printing?

● Manufacturing Expertise: We don't just print; we engineer for manufacturing.

● Speed & Precision: Fast turnaround without compromising on quality.

● Seamless Transition: Your easiest path from rapid prototyping to mass production.

● Technical Support: Expert DFM and technical guidance from start to finish.

We chat