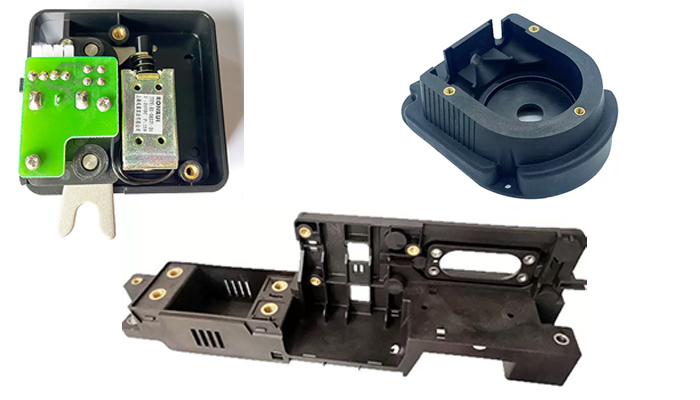

Precision Insert Molding Services for Complex Components

We are a leading insert molding manufacturer specializing in high- / low-volume, precision custom insert molding parts. Insert molding process integrate metal, electronics, and other substrates seamlessly into durable thermoplastic components to enhance performance, reduce assembly costs, and improve reliability. Ubetter Plastic often used is metal, like brass insert nuts, stamping parts.

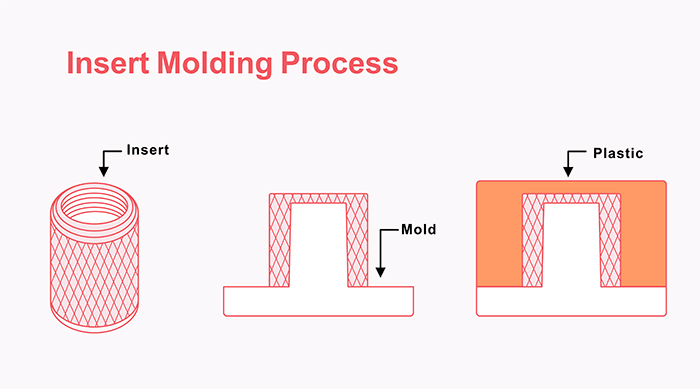

What is Insert Molding?

Insert molding, also known as metal insert molding or plastic insert molding, is an advanced manufacturing process where a pre-formed component (the "insert") is placed into an injection mold. Molten thermoplastic is then injected into the mold, encapsulating the insert and forming a single, unified part upon cooling.

This process is distinct from OverMolding, which typically involves molding a layer of plastic over another plastic substrate. The insert molding process is specifically designed to combine dissimilar materials—such as metal, ceramic, or electronic components—with engineering-grade plastics, creating robust and multifunctional components that are impossible to achieve with traditional assembly methods.

Key Benefits of Choosing Insert Molding Services

1. Enhanced Structural Integrity and Part Consolidation

By combining multiple parts into a single, cohesive unit, insert molding eliminates the need for screws, adhesives, or press-fitting. This part consolidation results in superior structural strength, reduced points of failure, and a product that is inherently more durable. Our expertise in insert molding design ensures optimal material selection and geometry for maximum performance.

2. Improved Reliability and Sealing Properties

The thermoplastic molding process creates a permanent, hermetic seal around the molded inserts. This provides exceptional resistance to vibration, moisture, chemicals, and corrosion, making it ideal for demanding applications in automotive, medical, and consumer electronics. Your components are protected for the long term.

3. Streamlined Assembly and Significant Cost Reduction

Insert molding services dramatically lower your total production costs. By automating the assembly process within the mold, we reduce labor, minimize the use of secondary fasteners, and decrease the chances of assembly-line errors. This efficiency translates into faster production times and a lower total cost of ownership for your products.

4. Design Flexibility for Complex Applications

The insert molding process offers unparalleled design freedom. It allows for the integration of complex features, such as internal channels, reinforced threads, and fully encapsulated electronics. Whether you need to embed a brass insert for screw threads or a sensitive sensor for a smart device, this process can bring your innovative designs to life.

Our Expertise in Custom Insert Molding Manufacturing

Advanced Insert Molding Materials and Technologies

We work with a wide range of engineering-grade thermoplastics (such as Nylon, PC, ABS, PEEK) and compatible insert materials (including brass, stainless steel, and ceramics). Our state-of-the-art Injection Molding machines, coupled with robotic automation for precise insert placement, ensure consistent quality and high-volume production efficiency for every project.

One-Stop Insert Molding Services

As your comprehensive insert molding supplier, we provide support at every stage. Our services include:

● Design for Manufacturability (DFM) Consultation: Our engineers will optimize your insert molding design for cost, performance, and manufacturability.

● Precision Mold Making: We build high-precision molds in-house to guarantee the accuracy of your custom insert molding parts.

● Full-Scale Production & Automation: We leverage automated systems for high-volume production, ensuring each molded insert is perfectly positioned and encapsulated.

● Rigorous Quality Control: Every batch undergoes stringent inspection to meet your exact specifications.

Quality Assurance

Quality is embedded in our insert molding process. From initial material inspection (IQC) to in-process checks (IPQC) and final random audits (OQC), we adhere to strict quality protocols. Our commitment to precision ensures that every component we produce meets the highest standards of durability and performance.

Industries and Applications for Insert Molding

Our custom insert molding solutions are critical to innovation across numerous industries. Explore how we help engineers solve complex challenges:

● Automotive: Producing durable sensor housings, electrical connectors, and under-the-hood components with metal insert molding for enhanced heat and vibration resistance.

● Medical Devices: Manufacturing reliable surgical instrument handles, connectors for fluid management, and single-use device components that require a sterile, sealed interface between metal and plastic.

● Consumer Electronics: Creating waterproof connectors, reinforced button assemblies, and structurally sound housings with insert molding for electronics that protect delicate internal components.

● Home Appliances & Tools: Developing robust components with integrated brass inserts for strong threading in power tools and kitchen appliances, ensuring long-term durability.

Insert Molding FAQs

Q1: What is the difference between insert molding and overmolding?

While both involve combining materials, insert molding specifically refers to placing a solid, pre-made insert (like metal) into a mold to be encapsulated by plastic. Overmolding typically involves molding a layer of plastic (e.g., a soft TPE grip) over another plastic substrate. The key difference is the nature of the substrate being encapsulated.

Q2: What types of inserts can be used in the insert molding process?

Virtually any component that can withstand the heat and pressure of the thermoplastic molding process can be used. Common examples include metal screws, pins, brass insert nuts, stamping parts, electrical contacts, sensors, and ceramic substrates. We can advise on the best insert material for your application.

Q3: What are the key considerations for insert molding design?

Critical design factors include: ensuring the insert has features (like knurls or holes) for the plastic to grip onto, accounting for differences in thermal expansion between the insert and plastic, and designing the mold to precisely locate and hold the insert during injection. Our engineering team provides insert molding design support to address these factors.

Q4: How do you ensure the precision and stability of the molded inserts?

We use precision-machined molds and, where appropriate, automated robotic systems to place inserts with extreme accuracy. Our process parameters (temperature, pressure, injection speed) are meticulously controlled to prevent insert movement or deformation, guaranteeing the stability and consistency of every part.

Ready to Start Your Insert Molding Project?

Partner with us to leverage our expertise as a leading insert molding manufacturer. We are committed to delivering high-quality, cost-effective solutions that push the boundaries of what's possible. From initial concept to high-volume production, we are your trusted insert molding supplier.

Contact us today for a free project review and quotation. Let's discuss how our insert molding services can enhance your product.

Upload Your CAD File for a Preliminary Quote

We chat