OverMolding Service for Durable and Ergonomic Products

As a specialized injection molder, we leverage advanced overmolding and two-shot molding technologies to create multi-material parts that enhance functionality, comfort, and value.

What is Plastic Overmolding?

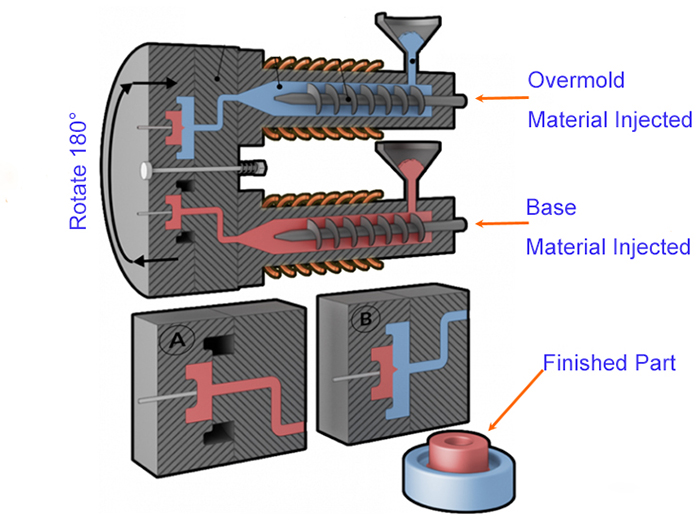

Overmolding is a multi-step Injection Molding process where a substrate (often a rigid plastic or metal part) is partially or completely encapsulated by a second material, typically a soft thermoplastic elastomer (TPE) or silicone. This creates a single, integrated component with the distinct properties of both materials, eliminating the need for secondary assembly and resulting in a more robust and user-friendly product.

Benefits of the Overmolding Process

Our overmolding services provide numerous advantages that can give your product a competitive edge:

·Enhanced Ergonomics and Improved Grip: The soft-touch surface provides superior comfort and slip resistance, ideal for handheld devices, tools, and medical equipment.

·Increased Durability and Impact Resistance: Protect internal components from shock, vibration, and abrasion, extending the product's lifespan even in harsh environments.

·Superior Sealing and Waterproofing: Create airtight and watertight seals integral to the part, perfect for consumer electronics and automotive components that require IP-rated protection.

·Aesthetic Appeal and Brand Differentiation: Combine colors, textures, and materials to create a high-quality, unique look that strengthens brand identity.

·Reduced Assembly and Lower Overall Cost: By combining multiple parts into one, we eliminate steps like gluing or mechanical fastening, streamlining production and reducing labor costs.

Our Overmolding Capabilities and Materials

Two-Shot Molding vs. Insert Molding

We possess the expertise and equipment to handle both primary Overmolding techniques, ensuring the most efficient method is selected for your project:

·Two-Shot Molding (2K Molding): This advanced process involves injecting two different materials into a single mold during one continuous cycle on a specialized two-shot molding machine. It offers exceptional precision, high production speeds, and superior material bond strength between the substrate and overmold.

·Insert Molding: In this process, a pre-formed substrate (which could be plastic, metal, or even a circuit board) is placed into a mold. The second material is then injected around it, forming a permanent bond.

Our engineering team will analyze your design (like parts structure, proejct budget) to recommend the most cost-effective and reliable method, whether it's two-shot molding or insert molding.

Common Material Combinations for Overmolding

The success of an overmolded part hinges on selecting compatible materials with strong adhesion. We have extensive experience with a wide range of thermoplastics and elastomers:

Rigid Substrate Material | Overmold Material | Common Applications |

ABS | TPE/TP | Power tool handles, consumer electronics |

Polycarbonate (PC) | TPE/Silicone | Medical device housings, transparent parts |

Nylon (PA) | TPU | Automotive connectors, high-wear components |

Polypropylene (PP) | Soft-touch TPE | Ergonomic grips, household goods |

We guide you through material selection to achieve the desired functionality, durability, and compliance standards for your industry.

Applications of Overmolded Parts

Our overmolding service is ideal for a wide range of industries that require robust, user-friendly components.

Medical Device Manufacturing

We produce high-precision, biocompatible overmolded parts for the medical industry, including ergonomic surgical tool grips, sealed housings for diagnostic equipment, and comfortable wearable devices. Our processes ensure compliance with stringent quality standards.

Consumer Electronics and Tools

From soft-touch grips on power tools and comfortable handles on hair appliances to waterproof casings for smartphones and remote controls, we enhance the usability and durability of everyday products.

Automotive Components

We manufacture reliable automotive components that withstand harsh conditions. Our expertise includes creating sealed electrical connectors, vibration-dampening pads, and interior trim pieces with appealing soft-touch surfaces.

Industrial Equipment

We produce durable grips, protective bumpers, and environmental seals for industrial equipment. Overmolded parts can help improve operator safety and comfort while protecting machinery from impact and wear.

Why Choose Us as Your Overmolding Partner?

·Expertise in Multi-Material Molding: With over 16 years of experience, we solve complex design challenges to deliver flawless multi-material parts.

·DFM (Design for Manufacturability) Support: Our engineers work alongside you during the design phase to optimize your part for the overmolding process, ensuring manufacturability, cost-efficiency, and superior material bond strength.

·Full-Service Solution: We support you from concept and prototyping through to high-volume production, ensuring consistency and quality at every stage.

·Stringent Quality Control: Every overmolded part undergoes rigorous inspection to meet your exact specifications and the highest quality standards.

Have a Project in Mind? Get a Free Quote Today!

Ready to enhance your product with overmolding? Contact our experts for a free consultation and quote. Upload your CAD files for a faster response.

Overmolding FAQs

Q1. What is the difference between overmolding and insert molding?

While both are multi-material molding processes, the key difference lies in the substrate. Overmolding typically refers to molding a soft material over a rigid plastic substrate. Insert Molding specifically involves molding plastic around a non-plastic insert, such as a metal pin, blade, or electronic component.

Q2. Which material bond strength is strongest for overmolding?

The strongest bonds are usually achieved between chemically compatible materials, such as ABS and TPE, or Nylon and TPU. Mechanical interlocking through undercuts in the part design also significantly enhances bond strength. Our engineers will select the best material combination for your application's requirements.

Q3. What are the key design considerations for an overmolded part?

Critical design considerations include:

·Material Compatibility: Ensuring a strong bond between the substrate and overmold.

·Wall Thickness: Managing the thickness of both materials to prevent sink marks or warpage.

·Gating and Flow: Designing the mold to allow proper flow of the second material around the substrate.

·Mechanical Interlocks: Incorporating undercuts and textures to enhance the physical bond.

We chat