Custom Plastic Injection Molding Services

From Prototype to High-Volume Production. We deliver high-quality, durable Custom Plastic Parts on time and within budget.

Request a Free Quote View Our Portfolio

Your Trusted Partner in Custom Injection Molding

Ubetter Plastic is a leading custom plastic injection molding manufacturer with over 16 years of expertise. We empower innovators across industries by turning complex designs into high-performance precision plastic parts. Our state-of-the-art facility, equipped with over 30 injection molding machines (ranging from 50 to 500 tons), is backed by a team of expert engineers dedicated to quality, efficiency, and your success.

Our Comprehensive Injection Molding Solutions

1. Prototype Injection Molding & Rapid Tooling

Get functional parts fast to validate your design, fit, and function before committing to high-volume production. Our rapid tooling and prototype injection molding services significantly reduce your product's time to market. We also provide rapid prototyping for your early project by 3D Printing.

2. High-Volume Injection Molding Production

Scale with confidence. Our automated production cells and rigorous quality control processes ensure consistent part quality, exceptional reliability, and competitive pricing for your large-scale manufacturing needs.

3. Insert Molding & OverMolding Services

Enhance part functionality and assembly efficiency. Our expertise in insert molding (encasing metal/electronic components) and overmolding (combining multiple materials) creates strong, multi-material components in a single, streamlined process.

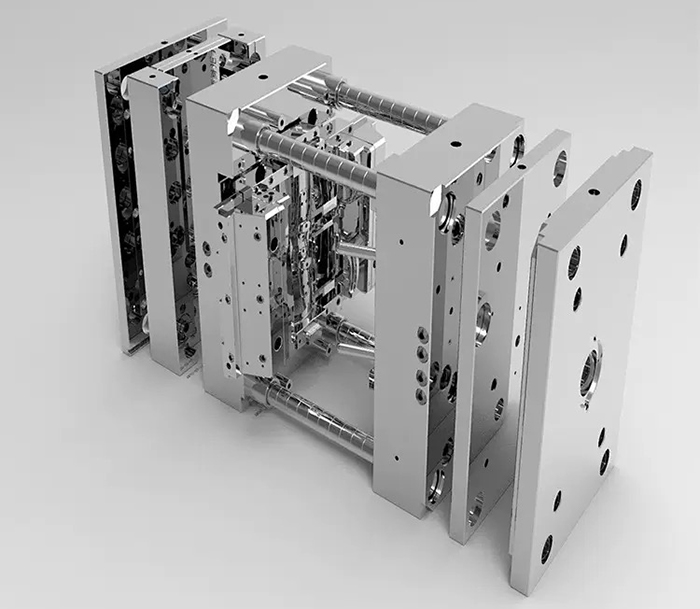

4. Custom Mold Design & Fabrication

The foundation of great parts is a great mold. Our in-house mold design and fabrication team uses advanced software and machining technology to build durable, efficient tools that optimize part quality and production lifecycle cost.

Serving a Wide Range of Industries with Precision Plastic Parts

1. Automotive Parts Injection Molding

Durable components for Interior trim, dashboards, bumpers, light housings, fluid reservoirs, and electronics that meet strict automotive standards.

2. Medical Device Manufacturing

High-precision parts for diagnostic equipment, surgical tools handles, Syringes, IV components, and drug packaging container.

3. Consumer Goods

Custom plastic parts for household containers, toys, kitchenware, appliance housings, bottle caps.

4. Electronics

Custom plastic parts for connectors, smartphone cases, keyboard keys, sensor housings.

Core Advantages of Injection Molding

1. Mass Production: High output (1,000+ parts/hour) with minimal waste.

2. Precision & Consistency: Tolerance as tight as ±0.05 mm.

3. Material Diversity: Works with 300+ materials (e.g., PP, ABS, PC, nylon, biodegradable resins).

4. Complex Geometry: Creates intricate shapes, thin walls (0.5 mm), and textured surfaces.

5. Cost-effective at large scale production.

What is Plastic Injection Molding?

Plastic injection molding is a versatile and efficient manufacturing process for producing large volumes of identical, high-quality plastic parts. It's the method behind millions of products we use every day, from automotive components and medical devices to consumer electronics.

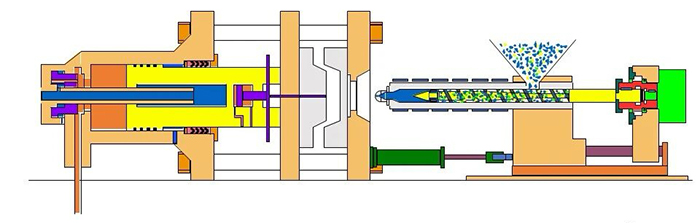

The injection molding process begins with feeding small plastic pellets (thermoplastic granules) into a heated barrel. An auger screw melts the pellets and injects the molten plastic under high pressure into a custom-designed, metal mold cavity. The plastic cools and solidifies into the shape of the mold. Once cooled, the mold opens, and the finished part is ejected, ready for use or assembly.

How Does Plastic Injection Molding Work?

The injection molding cycle is a highly coordinated and automated process that can be broken down into a few critical stages. Understanding these steps highlights the engineering expertise required to produce superior parts.

Clamping

The two halves of the precision-crafted mold are securely closed and held together by the clamping unit of the injection molding machine. The immense clamping force prevents the mold from bursting open under the high injection pressure.

Injection

Plastic pellets (or thermoplastics) are fed from the hopper into a heated barrel. A rotating screw melts the pellets as it moves backward. Once a sufficient amount of molten plastic—called a "shot"—is accumulated, the screw plunges forward like a piston, injecting the molten polymer into the mold cavity under high pressure.

Cooling

The molten plastic inside the mold begins to cool and solidify, taking the shape of the cavity. The cooling time is critical and is determined by the part's thickness and the material's properties. Proper cooling prevents defects like warping or sinks.

Ejection

After the designated cooling time, the mold opens. Ejector pins built into the mold plate extend to gently but firmly push the finished plastic part out of the mold cavity. The mold then closes again, ready for the next cycle.

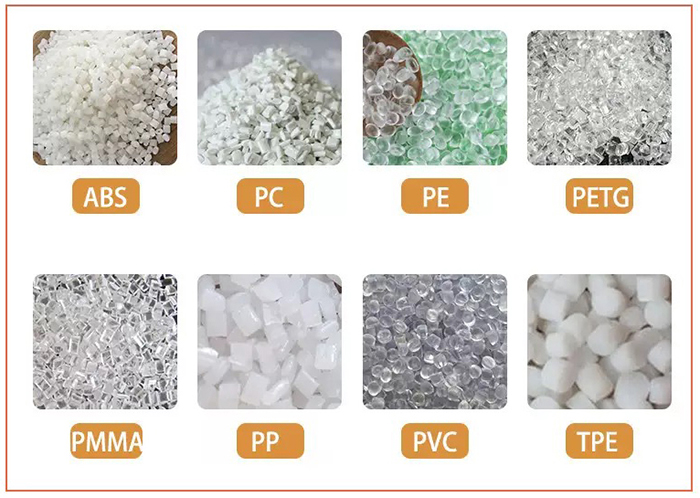

Custom Plastic Injection Molding Materials

There are many kinds of injection molding materials, with over 300 plastics nowadays. Here are 16 commonly used plastic resins listed for reference.

·ABS (Acrylonitrile Butadiene Styrene)

A widely used thermoplastic polymer with strong mechanical properties and good processability, commonly applied in producing toys, automotive parts, and electronic device casings.

·PP (Polypropylene)

A material with high heat resistance, chemical resistance, and rigidity, commonly used for automotive parts and household appliances.

·PE (Polyethylene)

It is a lightweight, flexible thermoplastic with good chemical resistance. Based on density, it is classified into high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

·PS (Polystyrene)

It is a transparent, lightweight plastic with good insulating properties, widely used in disposable tableware and packaging materials.

·PMMA (Polymethyl Methacrylate)

Commonly known as acrylic, it is a thermoplastic plastic prized for its excellent transparency and weather resistance, and is frequently used in lighting fixtures and billboards.

·POM (Polyoxymethylene)

This engineering plastic offers high crystallinity, strength, and rigidity, and is ideal for precision parts and gears.

·PVC (Poly(Vinyl Chloride))

This material offers good chemical resistance, mechanical strength, and electrical insulation, and is widely used in piping, electrical cables, and medical devices.

·PA (Polyamide)

Also known as nylon, it is an engineering plastic characterized by high strength, toughness, and wear resistance, making it suitable for manufacturing bearings, gears, and fibers.

·PC (Polycarbonate)

It is known for its excellent transparency, impact resistance, and temperature resistance, making it a common choice for manufacturing eyeglass lenses, bulletproof glass, and protective covers.

·PF (Phenol-Formaldehyde)

Also known as Bakelite, it is a thermosetting plastic with good mechanical properties and heat resistance, commonly used in electrical insulation components.

·EP (Epoxide Resin)

It is a thermosetting plastic with excellent adhesive properties and electrical insulation, making it widely used in coatings, adhesives, and electronic encapsulants.

·PS (Polystyrene)

This material is an excellent electrical insulator, colorless and transparent, and has light transmittance comparable to acrylic.

·PETG

A transparent, durable material that offers heat and chemical resistance.

·PBT (Polybutylene Terephthalate)

PBT resin offers excellent processability, electrical properties, and good surface finish quality.

·TPU

Molded TPU parts exhibit excellent abrasion resistance and flexibility.

·PEEK (Poly(ether-ether-ketone))

PEEK material offer high strength, stiffness, and chemical resistance.

Plastic Parts Surface Finishing Options

We will provide the optimal surface treatment for plastic parts tailored to our customers’ requirements. Surface treatment like Silk screen, Electroplating, UV coating, Water transfer printing, and Laser engraving.

Why Partner with Ubetter Plastic for Custom Injection Molding?

1. Advanced Molding Technology

We utilize all-electric and hybrid injection molding machines for superior precision, energy efficiency, and repeatability.

2. Stringent Quality Control

From first article inspection to statistical process control (SPC), our dedicated QC team ensures every part meets your specifications.

3. Expert Engineering Support

Our engineers provide invaluable Design for Manufacturability (DFM) analysis to optimize your part design for performance and cost-saving before production begins.

4. Competitive Pricing & Cost-Effective Solutions

We identify efficiencies in material selection, tool design, and production to deliver the best value without compromising on quality.

5. On-Time Delivery, Every Time

We understand your supply chain depends on reliability. Our robust project management ensures your deadlines are always met.

Our Seamless Injection Molding Process

1. Consultation & Quote: You share your part design or concept, and we provide a detailed analysis and transparent quote.

2. Mold Design & Engineering: Our engineers create a optimized mold design and provide a DFM report.

3. Material Selection: We help you choose the right polymer or thermoplastic for your application's requirements.

4. Precision Tooling & Mold Making: The custom mold is fabricated to the highest standards in our tooling shop.

5. Injection Molding Production: Parts are manufactured using our advanced injection molding machines under strict process monitoring.

6. Quality Assurance & Inspection: Every batch undergoes thorough inspection and testing to ensure compliance.

7. Delivery & Support: Your finished parts are carefully packaged and delivered, with ongoing account management support.

Ready to Bring Your Project to Life?

Get an online quote and injection molding design for manufacturability (DFM) analysis today. Upload your CAD drawings and specifications, and our engineering team will provide expert feedback and competitive pricing.

Injection Molding FAQs

Q1. What is the typical lead time for a custom injection molding project?

Lead times vary based on project complexity. Simple projects can take 3-5 weeks from mold design to first samples. High-volume production can be set up in 2-4 weeks. We provide a detailed timeline with your quote.

Q2. What types of materials do you work with?

We work with a wide range of engineering-grade thermoplastics, including Nylon, Polycarbonate, ABS, Polypropylene, PEEK, and TPEs/TPUs. We help you select the best material for strength, flexibility, temperature, chemical resistance, or aesthetic needs.

Q3. Do you provide design for manufacturability (DFM) analysis?

Absolutely. Our DFM analysis is a core part of our service. We identify potential production issues, recommend design modifications to reduce cost, and ensure your part is optimized for the injection molding process before any tool is made.

Q4. What is the difference between injection molding and insert molding?

Injection molding is the general process of injecting molten plastic into a mold. Insert molding is a specific technique where a pre-formed component (like a metal insert) is placed into the mold, and plastic is injected around it, creating a single unified part.

We chat